Fall Protection Systems

- Fall Protection Overview

Bridge Systems

Free Standing Cantilevered Monorail

Ceiling Mounted Monorail System

Fold Away Systems

Swing Arm Systems

Single Pole Systems

Fall Protection Systems – Tether Track

What is a Fall Protection System?

“Falls are among the most common causes of serious work related injuries and deaths. Employers must set up the workplace to prevent employees from falling off of overhead platforms, elevated work stations or into holes in the floor and walls.”

– Occupational Health and Safety Administration (OSHA)

A Fall Arrest or Fall Protection System is an active means of protecting workers from injury due to falls. A complete personal fall arrest system includes an anchor, a body harness and a connector- such as a shock-absorbing fall arrest lanyard or self-retracting lanyard (SRL).

What is Gorbel’s Tether Track Fall Protection System?

Using a Gorbel Tether Track™ Rigid Rail Fall Arrest System as your anchor provides workers with a high degree of mobility and freedom, while preventing falls to lower levels. Standard systems are designed to accommodate multiple workers, each weighing up to 310 pounds with tools.

Why choose Gorbel for Fall Protection Solutions?

Gorbel Tether Track™ Rigid Rail Fall Arrest Systems provide a reliable and cost-effective solution for reducing the risk of injury in elevated work environments. Available in various configurations, including multiple track profiles and support center distances, fall protection can be easily customized to fit every budget and application. All systems are designed by qualified engineers to meet the OSHA 1926 Subpart M construction standard, as well as the ANSI Z359 Fall Protection code.

Photos

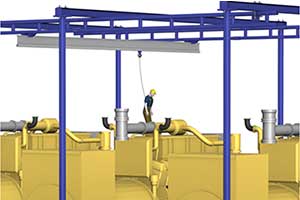

Tether Track Bridge System

CEILING MOUNTED SYSTEMS use the structure for support, as the rail is mounted either perpendicular or parallel to the ceiling beams. Should overhead obstacles be present, drop rod hangers with sway bracing can be supplied so that the system avoids these obstructions.

FREESTANDING SYSTEMS may be preferred whenever floor space is readily available to install column supports, when changes in work practices are anticipated, and when a building structure isn’t available. The flexibility of free standing systems allows them to be easily modified and moved should processes or fall protection needs change.

Multiple bridges can be supplied for both ceiling mounted and freestanding systems, thus allowing multiple workers to utilize the system simultaneously.

Features & Benefits

- Rectangular coverage area

- Up to 18′ bridge spans

- Consists of two runways and a traveling bridge for maximum coverage within a rectangular work area

- Lightweight aluminum bridge follows the worker, remaining directly overhead

- Designed for workers up to 310 lbs. with tools when used with 900 lbs. Maximum Arresting Force (MAF) energy absorbing lanyards, properly rated full-body harness and connecting device

- Multiple bridges can support several workers when properly zoned

Photos

Options

- Available in ceiling mounted or free-standing designs

- Plain or trussed track runways based on support center requirements

- Unlimited runway lengths, with up to 18’ standard maximum bridge spans – longer bridge lengths as custom if required (contact customer service)

- Multiple bridges can support several workers when properly zoned

- Motorized bridges

- Special finishes available based on application requirements

- Recover Trolley

Applications

- Enclosed track / easy movement and long life

- Rigid runways / superior load positioning – no movement or “crab walking” of the bridge

- Ease of Installation / install on any standard 6″ concrete floor

- Smooth rolling surface / Easier movement of bridge and trolleys

- Multiple track profiles and spanning capabilities/Adaptable, flexible, and cost competitive

Case Studies

Free Standing Cantilever Monorails

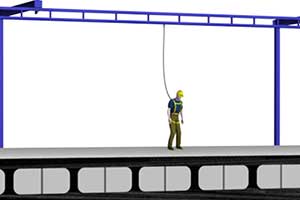

Tether Track Free Standing Monorails

Free Standing Monorail Fall Protection Systems are available in heights up to 26 feet to effectively protect workers maintaining, inspecting, or loading/unloading railcars, tankers or flatbed trucks.

- Standard heights from 16’ to 26’ make system ideal for applications such as rail car or flatbed loading and unloading

- Standard lengths up to 204’ Single and Dual Track Styles

Features & Benefits

- Dual bypassing track allows workers to safely pass each other without disconnecting

- Outdoor coatings available for maximum protection in outdoor environments-also includes corrosion resistant hardware

- Systems designed for wind, snow, and ice loads

- Integral trolley easily moves on enclosed track to keep fall arrest system in vertical plane

- Designed for workers up to 310 lbs. with tools when used with 900 lbs. Maximum Arresting Force (MAF) energy absorbing lanyards, properly rated full-body harness and connecting device

- Goal post design, comprised of two columns and a header, also readily available

Photos

Options

- Enclosed track / easy movement and long life

- Rigid runways / superior load positioning – no movement or “crabwalking” of the bridge

- Ease of Installation / install on any standard 6″ concrete floor

- Smooth rolling surface / Easier movement of bridge and trolleys

- Multiple track profiles and spanning capabilities/Adaptable, flexible, and cost competitive

- Special finishes available based on application requirements

- Recover Trolley

Ceiling Mounted Monorail Systems

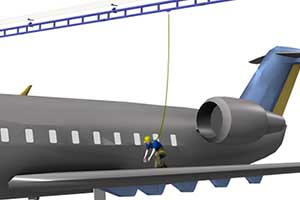

When floor space is at a premium, ceiling mounted monorails can provide unparalleled fall protection while maintaining an open floor plan for material handling, production, or related activities. Ceiling mounted monorails use existing support steel for overall anchorage strength, and are ideal for production facilities and warehouses with tall ceilings since column support is not needed. Even if the facility has standard ceiling heights, the compact, low-profile design of ceiling mounted monorails provides full protection without headroom concerns.

Features & Benefits

- Provides mobility along a single axis for applications when workers need to travel in a straight line

- Curved track sections available

- Variety of hanger options available to accommodate various building structures

- Unlimited monorail lengths with up to 50’ between supports (dual trussed track only)

- Systems are designed for workers up to 310lbs with tools when used with 900LB Maximum Arresting Force (MAF) energy absorbing lanyards, properly rated full-body harnesses and connecting device

- Track can accommodate single or multiple workers, dual bypassing track allows workers to safely pass each other without disconnecting

- Fall Clearance Calculations

Photos

Options

- Enclosed track / easy movement and long life

- Rigid runways / superior load positioning – no movement or “crabwalking” of the bridge

- Ease of Installation / install on any standard 6″ concrete floor

- Smooth rolling surface / Easier movement of bridge and trolleys

- Multiple track profiles and spanning capabilities/Adaptable, flexible, and cost competitive

- Special finishes available based on application requirements

- Recover Trolley

Case Studies

Fold Away Systems

The concept of a Fold-Away Fall Arrest System is simple: Deploy it when you need it, and fold it back when you’re done, maintaining productivity without compromising safety. The Tether Track™ Fold Away Fall Arrest System is the perfect solution for work cells requiring access to overhead cranes, when valuable floor space is limited, or when infrequent fall protection is necessary.

Features & Benefits

- Deploy as needed, then fold away when done; maintaining productivity without compromising safety

- Perfect solution for work cells requiring access of overhead cranes, when floor space is limited or when infrequent fall protection is necessary

- Trussed track to accommodate single or multiple workers and allow bypass

- Unlimited lengths with up to 50’ between supports

- Arm spans up to 20′

- Track can accomodate single or multiple workers, dual bypassing track allows workers to safely pass each other without disconnecting

- Designed for workers up to 310 lbs. with tools when used with 900 lbs. Maximum Arresting Force (MAF) energy absorbing lanyards, properly rated full-body harness and connecting device

- Designed by qualified engineers to meet the OSHA 1926 Subpart M Construction standard, ANSI Z359 Fall Protection Code, and NIOSH guidelines

Options

- Wall Mounted, Column Mounted, or Free Standing Designs

- Available in Wall Cantilever or Wall Bracket Configurations based on headroom constraints

- Optional friction brake for system positioning

- Motorized rotation available

- Special finishes available based on application requirements

- Recover Trolley

Applications

- For work cells requiring access to overhead cranes

- When floor space is limited

- When infrequent fall protection is necessary

Case Studies

Swing Arm Systems

The Tether Track™ Swing Arm Fall Arrest System from Gorbel provides circular or semi-circular fall protection with a compact footprint. Versatile and infinitely variable, simply position the swing arm over the work space and swing it out of the way when not in use.

Features & Benefits

- Provides circular or semicircular fall protection with a compact footprint

- Versatile and adaptable; the swing arm can be positioned over the work space when needed and moved out of the way when not in use

- Standard arm lengths from 8’ to 30’, custom spans available upon request

- Track can accommodate single or multiple workers, dual bypassing track allows workers to safely pass each other without disconnecting

- Designed for workers up to 310 lbs. with tools when used with 900 lbs. Maximum Arresting Force (MAF) energy absorbing lanyards, properly rated full-body harness and connecting device

- Designed by qualified engineers to meet the OSHA 1926 Subpart M Construction standard, ANSI Z359 Fall Protection Code, and NIOSH guidelines

Options

- Wall Mounted, Column Mounted, or Free Standing Designs

- Available in Wall Cantilever or Wall Bracket Configurations based on headroom constraints

- Optional friction brake for system positioning; required for multiple users

- Motorized rotation available

- Special finishes available based on application requirements

- Recover Trolley

Applications

- Tank car servicing

- For work cells requiring access to overhead cranes

- When floor space is limited

- When infrequent fall protection is necessary

Case Studies

Single Pole Systems

When numerous obstacles exist in the work space and standard multiple-column systems are not practical, single pole fall protection systems provide a convenient alternative. Used regularly in tank car servicing or heavy-duty truck securing and tarping areas, single pole systems require only a single foundation. Standard span lengths from 10′ to 53′ mean the system can be designed to meet the requirements of most loading/unloading and maintenance facilities.

Features & Benefits

- Space-saving design allows for installation in areas of minimal floor space or limited room for foundations

- Utilizes only one free standing support with one single foundation

- Standard track lengths up to 53′

- Track can accommodate single or multiple workers, dual bypassing track allows workers to safely pass each other without disconnecting

- Designed for workers up to 310 lbs. with tools when used with 900 lbs. Maximum Arresting Force (MAF) energy absorbing lanyards, properly rated full-body harness and connecting device

- Designed by qualified engineers to meet the OSHA 1926 Subpart M Construction standard, ANSI Z359 Fall Protection Code, and NIOSH guidelines

Options

- Special finishes available based on application requirements

- Recover Trolley

Applications

- Tank car servicing

- Heavy-duty truck securing

- Tarping areas

Case Studies

Call Us Today

1-800-517-7247

To learn more about our complete lineup of industrial overhead crane systems; or for answers to other material handling questions give one of our friendly staff members a call directly at 1-800-517-7247 or