R&M Crane Packages

QX® Wire Rope Cranes

QX® Wire Rope Cranes Nrgmaster Energy Chain Crane

Nrgmaster Energy Chain Crane ControlMaster® Anti-Sway Crane

ControlMaster® Anti-Sway Crane QL Electric Chain Hoist Crane

QL Electric Chain Hoist Crane QLP Push Crane

QLP Push Crane

QX® Wire Rope Cranes

QX® wire rope cranes are complete crane systems, featuring our top-ranked Spacemaster® SX wire rope hoist.

About QX® Wire Rope Cranes

R&M crane packages are designed to work as a complete system, so every component, from the hoist selection to the bridge drives and girder size, are designed to work together. This means you are getting a fully optimized package to maximize your floor coverage and make the best use of your building space! Many of our innovative features are included as standard on the QX wire rope crane package, to bring you the best performance, safety, and reliability available in the industry.

Standard Features

- Spacemaster® SX wire rope hoist with two-speed hoisting controls

- Top or underrunning design

- C-track festoon electrification system with UL listed cables

- PRQ ergonomic pendant controller

- Optional Racon® 3 radio controller

- HoistMonitor® or HoistWatch load monitoring system

- Standard inverter controls for trolley and bridge for reduced load swing

- NEMA 4 type rated control enclosures

- Plug-in connections for easy assembly and maintenance*

- 208, 230, 460 or 575/3/60 power supplies, as well as 380/3/50.

- 115 volt control voltage for all power supplies (48 volt optional)

- All components are CSA c/US approved

Why choose a QX wire rope crane package?

QX crane packages are a total solution for your material handling needs. Your components are optimized to give you the right equipment, right when you need it! We have utilized our nearly 90 years in the material handling business to carefully engineer these packages to be tailored to any application or facility. Each package is designed specifically to make the most of your space, bringing you the best in safety, reliability and flexibility.

Better Safety

Every QX wire rope crane package comes equipped with a HoistMonitor or Hoistwatch load monitoring system. This system prevents overloads, monitors the equipment usage, and provides helpful advanced service warnings to help you keep your equipment running safely and avoid costly downtime. Our 4-position hoisting limit includes an innovative phase reversal position which prevents the block from running into and damaging the hoist in the event of phase reversal.

Less Maintenance

Sealed dust-proof brakes on the motors are self-adjusting and impregnated with Kevlar for high-performance wear, designed for over a million cycles. Standard inverter control motions on the trolley and bridge safely slows the motor speed to zero before the brake sets. This speed ramp up and ramp down time reduces load swing and extends the life of the motor brake. R&M is committed to helping you rise above with less maintenance, less downtime, lower repair costs — and reduced cost over the lifetime of your hoist equipment.

Downloads

Spacemaster SX Wire Rope Hoists Brochure

R&M Product Line Card Brochure

Gallery

NRGMASTER ENERGY CHAIN CRANE

The NRGmaster energy chain crane features our innovative NRGmaster festoon and RaCon® 3 radio controller for the best floor coverage and ease of operation.

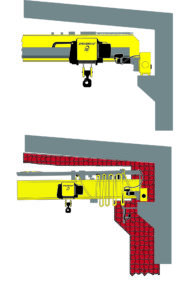

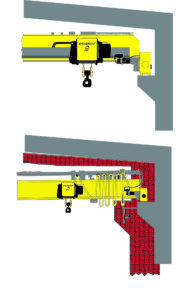

Energy Chain Cranes

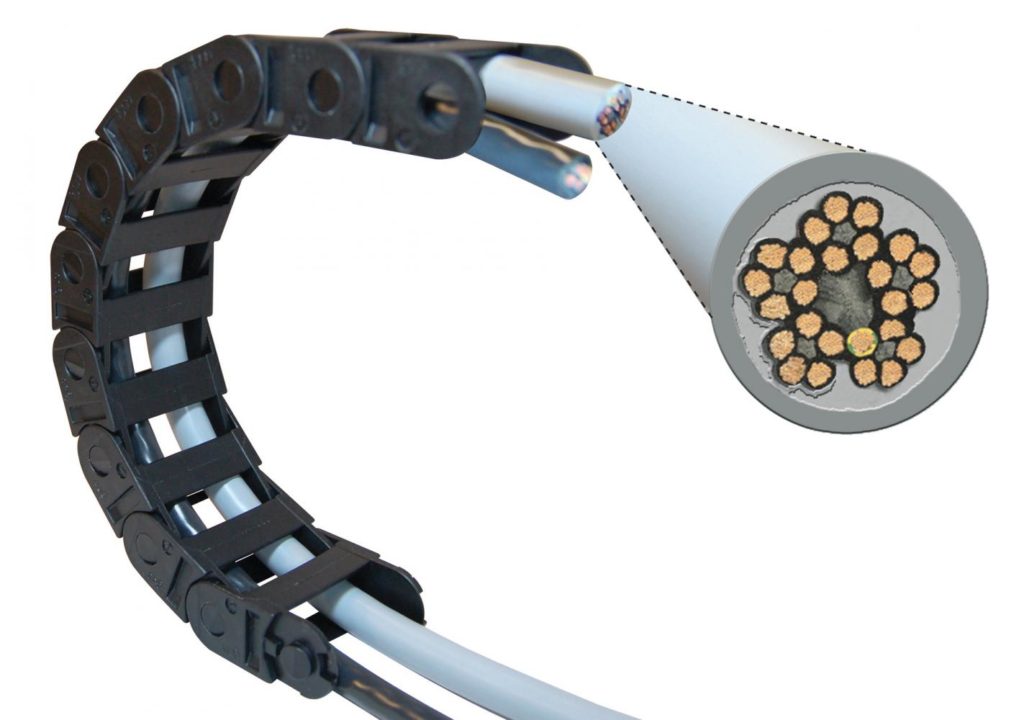

NRGmaster energy chain cranes feature an energy chain style crane electrification system that supplies power to the hoist. It is an alternative to the traditional C-track festoon system featured on the QX® modular crane. NRGmaster electrification consists of power and control cables that are enclosed in a flexible chain. The chain rests in a guide channel that is fastened to the web of the bridge girder. The free end of the chain bends into a U-shape and connects to the hoist tow arm while the other end fastens to the channel. The NRGmaster energy chain crane helps you achieve the best crane clearances and shop floor coverage while reducing the maintenance concerns associated with traditional C-track festoons.

Standard Features

- Spacemaster® SX wire rope hoist

- NRGmaster festoon with spans up to 100 ft (30 m)

- Maximum hoist capacity = 80 tons (80,000 kg)

- 1 or 2 hoists per bridge

- Racon 3 radio control with mini joystick included

- CSA c/US approved

Unmatched Clearance and Floor Coverage

Using a R&M crane package means the complete crane is designed to work together. The compact design of our Spacemaster coupled with optimized crane components and bridge girder design results in lower roof heights with maximum lifting heights and hook to wall dimensions. Your new building design can be smaller and more functional giving you savings in initial construction and continual savings in heating and/or air conditioning expenses over the lifetime of your building. The NRGmaster festoon gives you the most flexible options for your factory layout and material flow planning.

Easy Operation

The NRGmaster energy chain crane does not just look clean and simple – it helps you to simplify operations! The NRGmaster festoon system removes the maintenance concerns associated with a traditional C-track festoon. There are no dangling wires to snag on equipment, and the electrical cables are protected inside the energy chain with a much wider turning radius which helps to prevent broken wires. Additionally, the crane system comes standard with our Racon 3 radio for safer and more ergonomic operation of the crane.

Downloads

Spacemaster SX Wire Rope Hoists Brochure

R&M Product Line Card Brochure

Gallery

Nrgmaster Energy Chain Crane Video Overview

- Hoosier Crane NRGMaster Crane Electrification system

- R&M Hook Latch Trigger

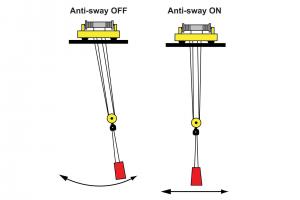

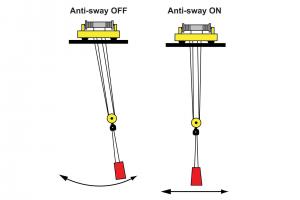

CONTROLMASTER® ANTI-SWAY CRANE

Automated anti-sway crane controls improve safety and increase productivity.

About ControlMaster® Anti-Sway Cranes

You put a lot of time, resources, and passion into what you produce – it is important to protect that investment! The ControlMaster Anti-Sway System’s seamless movement is perfect for controlling your most delicate and important lifts.

The ControlMaster Anti-Sway System is an option for the QX® modular crane package. When added to a crane, the ControlMaster Anti-Sway System allows the operator to move a load from one place to another without creating load sway. The operator is free to focus solely on the load and surrounding area, creating a load movement process that is both fast and safe. The ControlMaster Anti-Sway System automatically adjusts the crane traveling motions by using a mathematical calculation to estimate load swing. The calculation is based on the distance between the center of the rope drum and the load (pendulum length). The system maintains, accelerates, decelerates or reverses the travel speeds/directions to keep the hoist directly over top of the load.

Standard Features

- Spacemaster® SX wire rope hoist

- QX® modular crane package components

- Racon® 3 radio controller

- HoistMonitor® or HoistWatch condition monitoring unit

- ControlMaster inverter controls for trolley and bridge traveling motions

- ControlMaster Anti-Sway control module

- On-site calibration of the controls by R&M factory representative

Downloads

General Instructions and Inspection Instructions for Crane

Spacemaster SX Wire Rope Hoists Brochure

R&M Product Line Card Brochure

VIDEOS

QL ELECTRIC CHAIN HOIST CRANE

QL electric chain hoist cranes feature our HMI-CertifiedSM LK electric chain hoist. They are designed for rugged durability and ease of use.

About QL Electric Chain Hoist Cranes

R&M QL crane packages are designed to work as a complete system, so every component, from the hoist selection to the bridge drives and girder size, are designed to work together. This means you are getting a fully optimized package to maximize your floor coverage and make the best use of your building space! With standard features like inverter controlled trolley and bridge motions for smooth starts and stops, plug-and-play connections for easy assembly and maintenance, and the quietest chain hoist on the market, the QL electric chain hoist crane will help you rise above your material handling challenges.

Standard Features

- LK electric chain hoist with two-speed hoisting controls

- 1/2 – 5 ton (500 – 5,000 kg) capacities

- Single girder top running or single girder underrunning crane designs

- LK electric chain hoist with motorized trolley

- 208, 230, 460 or 575/3/60 power supplies

- Standard inverter controls for trolley and bridge for reduced load swing

- Crane spans up to 62 ft [19m]

- PRQ ergonomic pendant controller

- Optional Racon® 3 radio controller

- Durable C-track festoon electrification system with UL listed cables

- CSA c/US approved NEMA 4-3R type/IP55

Why choose a QL electric chain hoist crane?

QL electric chain hoist cranes are a total package solution for your light-duty material handling needs. The crane components have been designed as a complete system to maximize efficiency and optimize your floor space. As part of our offering, we are bringing you the best quality components available for electric chain hoist cranes in the market, including a C-track style festoon, all metallic hoist body and electrical enclosures, and our bridge and trolley drives that are designed in-house specifically for use on cranes.

Safety

Every LK electric chain hoist comes standard with our innovative slip clutch overload device, protecting you from dangerous accidental overloads. With the slip clutch device, if an operator attempts to lift a load beyond the rated capacity, the load will only be able to be lowered safely to the ground. Additionally, the LK electric chain hoist is equipped with a rocker style limit switch to prevents overtravel of the hook block into the hoisting machinery. The rocker limit design maximizes headroom and safety.

The crane is equipped with all inverter controlled trolley and bridge motions, meaning reduced load swing and better safety. The inverter controls also significantly reduce brake wear on the trolley and bridge.

HMI-Certified

The LK electric chain hoist line is HMI-Certified! The purpose of the HMI-Certified License program is to instill buyer and user confidence in the product by assuring it meets one or more recognized industry standards and the licensee is committed to safety, service and after market support. The product is also verified, signed and sealed that it meets the requirements of said Standards(s) by a qualified US registered Professional Engineer.

HMI-CertifiedSM is a registered asset of the Hoist Manufacturers Institute (HMI®).

Downloads

LK Electric Chain Hoist Brochure

R&M Product Line Card Brochure

Gallery

Call Us Today

1-800-517-7247

To learn more about our complete lineup of industrial overhead crane systems; or for answers to other material handling questions give one of our friendly staff members a call directly at 1-800-517-7247 or