R&M Wire Rope Hoists

Spacemaster® SX Wire Rope Hoist

Spacemaster® SX Wire Rope Hoist

R&M’s Spacemaster SX wire rope hoist comes standard with everything you need to get to work quickly and safely. This wire rope hoist can meet every lifting demand.

Standard electric wire rope hoist configurations include normal headroom, low headroom and double girder designs.

Standard Features

- 1/2 – 80 ton (500 – 80,000 kg) capacities

- Lifts at 13 – 320 ft (4 – 100m)

- Lifting speed range 10/1.5 – 62/10 fpm (3/0.5 – 19/3 m/min)

- 208, 230, 460, 575/3/60 or 380/3/50 power supply

- Single-reeved or double-reeved

- Load monitoring

- Two-speed hoisting and inverter controlled trolley motions

- Lowest headrooms in the industry

Why choose the SX hoist?

We are committed to helping you rise above the challenges of your every day business. The safety, reliability, and reduced maintenance of the Spacemaster SX wire rope hoist allows you to get the most out of your equipment.

Easy to Operate

Our innovative hoist design provides the best headroom in the industry while minimizing hook drift and maximizing end approaches. This means you get more floor coverage and easier operation of the equipment. Standard inverter controls on the trolley reduce load swing and minimize brake wear.

Safe

R&M offers load monitoring systems as standard with every wire rope hoist. The HoistMonitor and HoistWatch systems give you real information about your equipment use and service needs while preventing overloads to the crane.

Reliable

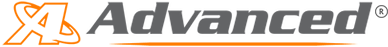

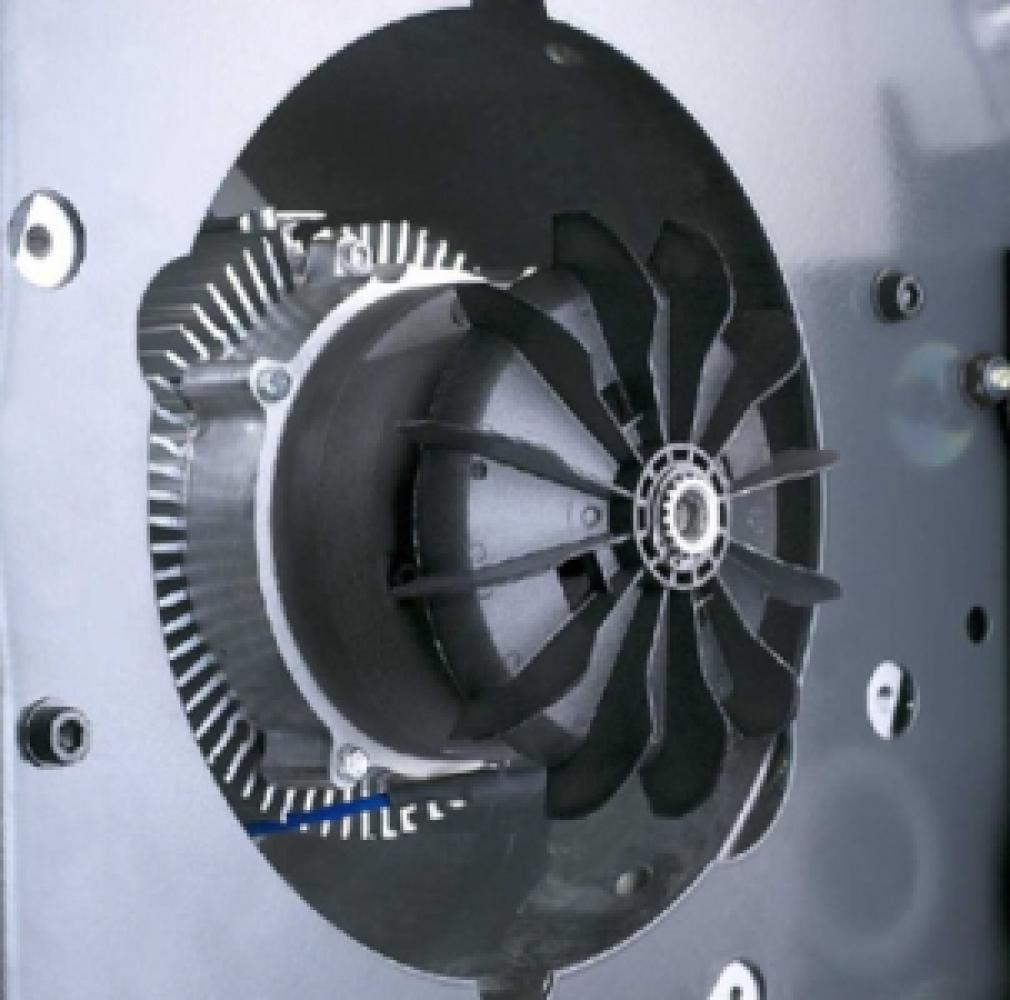

At R&M, all our equipment is designed in-house, specifically for lifting applications. The innovative gear case design reduces stress on drum bearings, lowering the need for maintenance and extending the life of the equipment. Our unique rope drum design, with 40:1 drum to rope diameter and motor inside the drum, provides the least hook drift in the industry while improving motor cooling efficiency.

Need something fast?

Our RX Program has a selection of wire rope hoists ranging from 1 to 40 tons, available in 2-5 business days! Ask a R&M Distributor for more information on this program.

Gallery

Spacemaster® SX Wire Rope Hoist Video Overview

- Spacemaster SX Wire Rope Hoists

- R&M Hook Latch Trigger

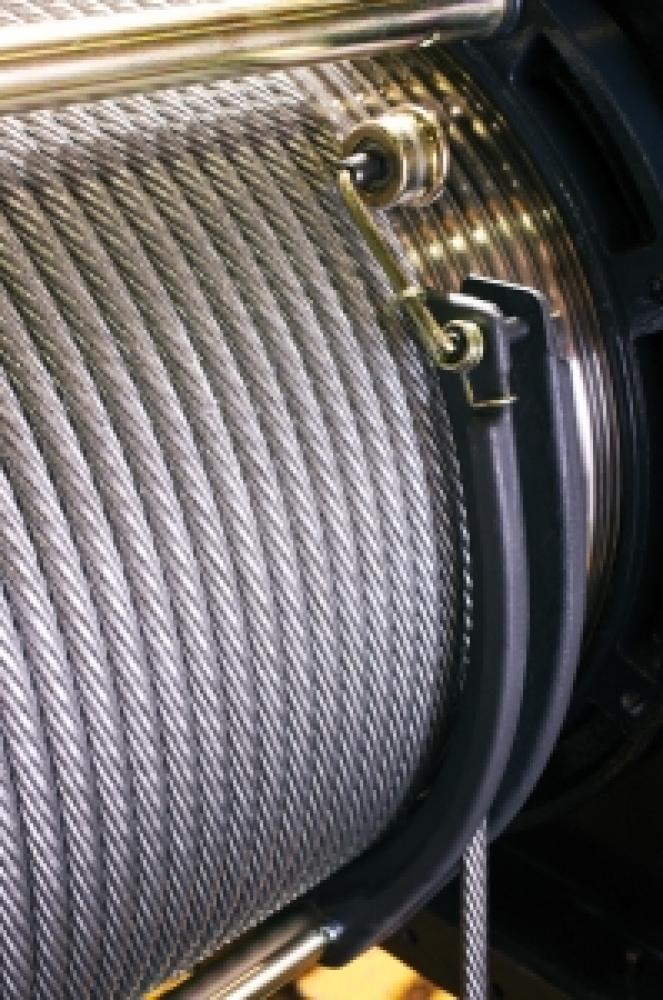

SXL Heavy Lifting Winches

SXL Heavy Lifting Winches

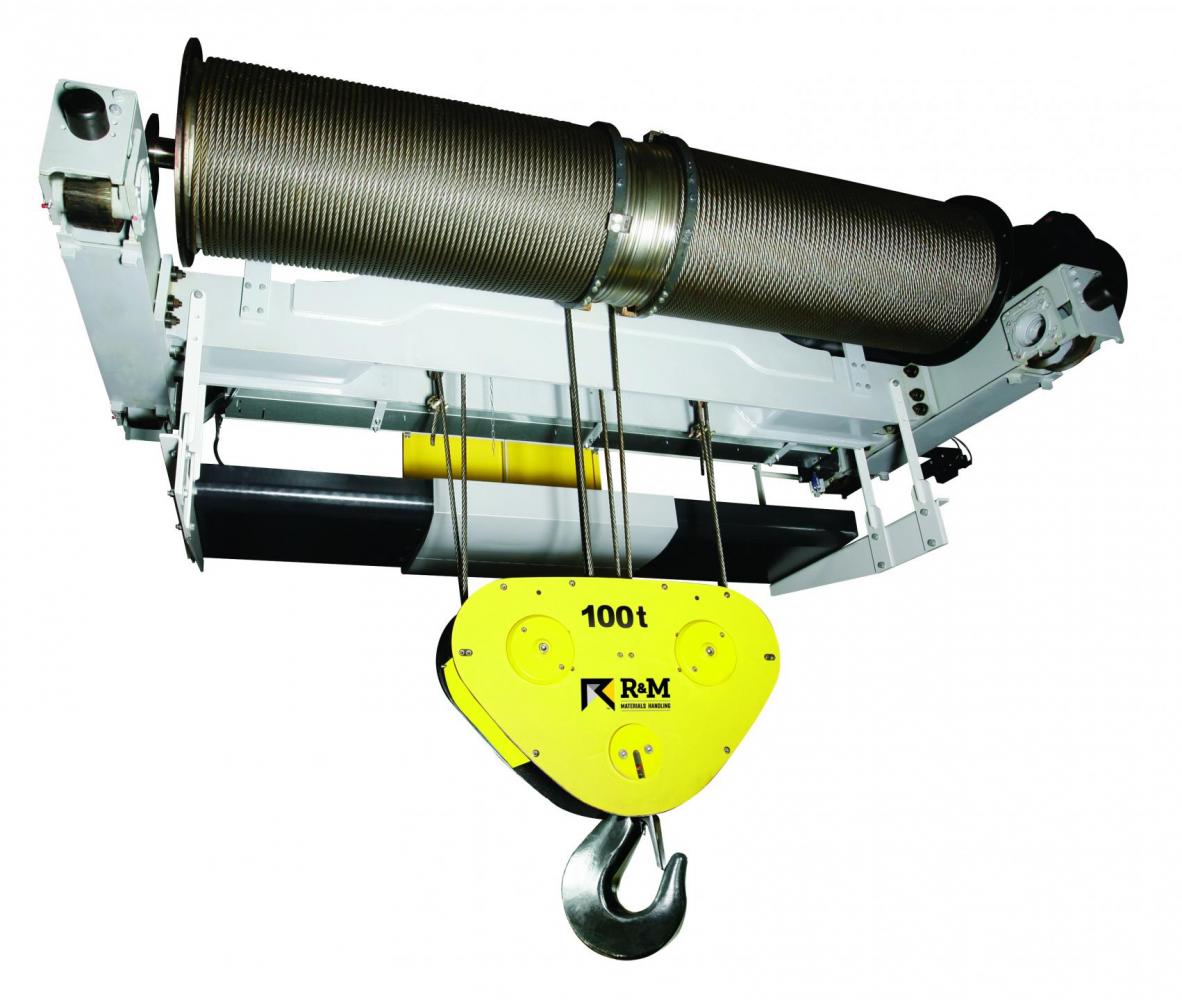

R&M’s SXL is an open winch electric overhead hoist, designed for demanding, heavy-duty applications, across a wide range of industries.

Heavy-duty lifting requires heavy-duty solutions. When you need a rugged hoist with high capacities and long lifts, the SXL open winch wire rope hoist is there to meet the most rigorous lifting demands.

Standard Features

- 10- 250 ton ( 10,000 – 250,000 kg) capacities

- CMAA/ASME or FEM/ISO duty ratings and CSA c/US certification

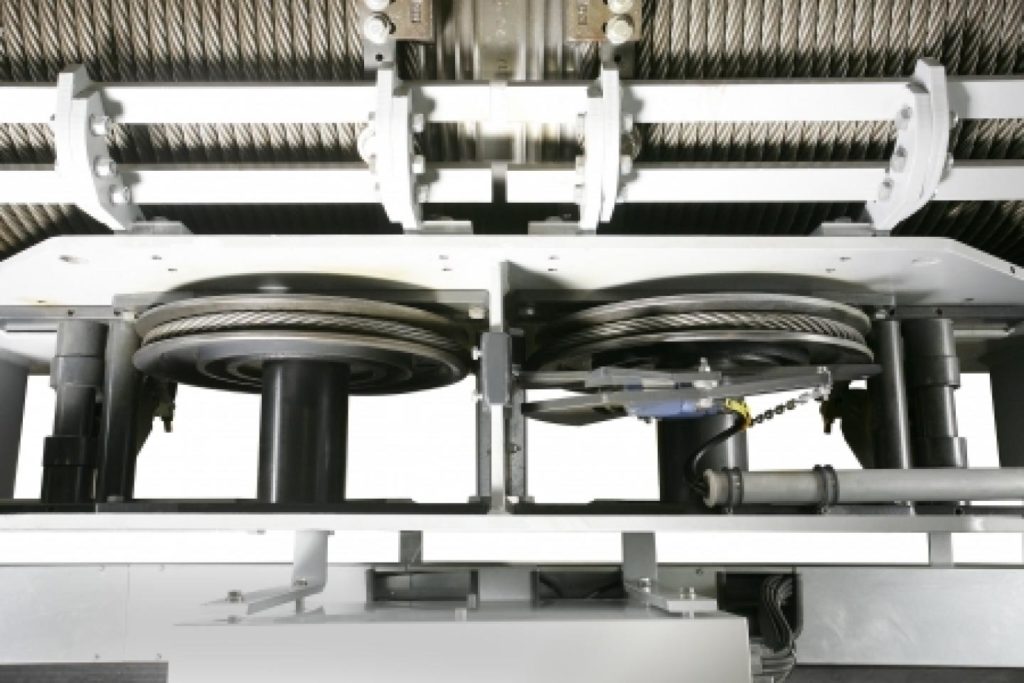

- Compact double girder trolley with double reeving for true vertical lifts

- Dual-trolley drives for powerful travel motion

- Motors with thermal protection and D.C. disk brake

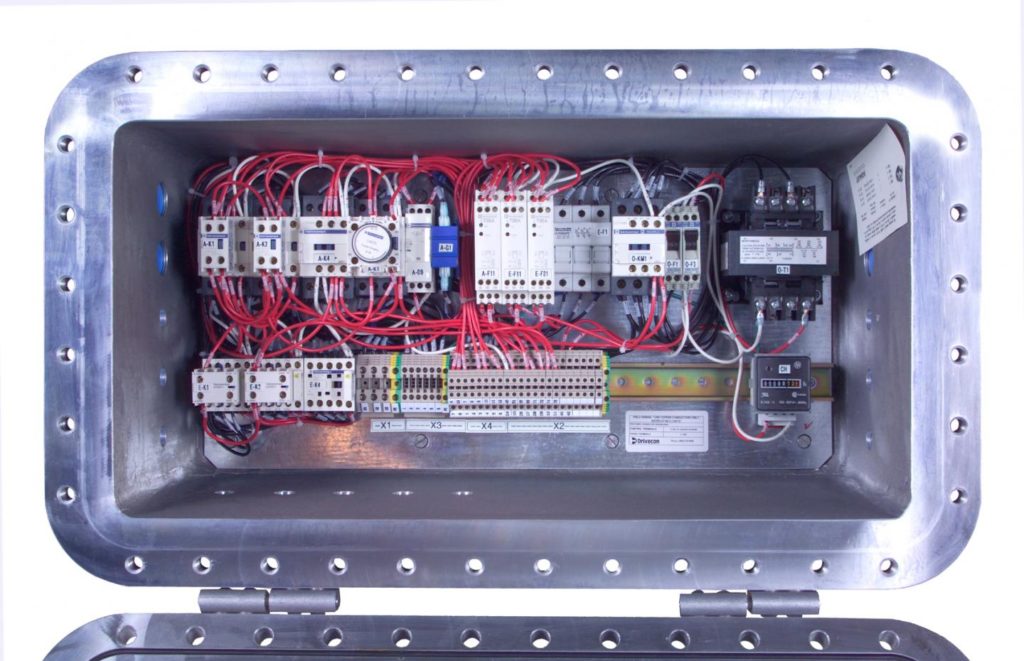

- HoistMonitor® featuring overload protection and condition monitoring

- Rope overwrap protection

- Inverter control for all motions with closed-loop vector control for hoisting

Designed for You

The SXL open winch hoist is tailored to meet your specific requirements. The modular design of the hoists and trolleys allow a wide variety of application-specific designs, with all the functionality of a custom built-up hoist. Choose from an abundance of special features, such as outdoor protection and special temperature ranges, specialty hooks and provisions for below the hook devices, precision load and sway controls, maintenance platforms, extra long lifts, and extra durable hardened hoist drum and sheaves.

Why choose the SXL?

The SXL open winch wire rope hoist is designed for strength and reliability, and engineered in-house specifically for heavy lifting applications. With operations this critical, nothing is more important than safety, reliability, and precision.

Safety

All SXL open winch wire rope hoists come equipped with the HoistMonitor® load monitoring system to control overloads and provide vital safety and performance data about the equipment. SXL hoists also include key safety features such as rope overwrap protection as standard. Additional features such as micro speeds and inching give the operator precise control of the load and increasing safety.

Reliability

The SXL’s rugged design starts at its core. All SXL winches are equipped with D.C. disk brakes for all motions, Class H insulation on the motors, and three-step helical gearing. This machinery is designed specifically for hoisting operations, meaning you are getting the most out of your equipment. The SXL open winch hoist’s unique rope drum design features a flexible two-stage geared coupling for dynamic bending and movement of the drum, reducing fatigue on the coupling.

Precision

SXL open winch hoists come standard with closed-loop vector controls, providing the most precise lifting experience available. Specialty controls also maximize the effectiveness of the equipment in your operations. Some of these features are load floating, anti-sway controls, hoisting synchronization, and extended speed ranges. Our controls packages are customizable to suit a wide variety of special applications.

Downloads

Spacemaster SXL Wire Rope Hoist Brochure

R&M Product Line Card Brochure

Gallery

Spacemaster® Ex Class I, Div 2 Hoist

Spacemaster® Ex Class I, Div 2 Hoist

The Spacemaster® EX wire rope hoist includes protective features against flammable gases and vapors found in hazardous locations.

About Our Hazardous Location Hoists

The Spacemaster® EX electric wire rope hoist is the hazardous location version of the industry-leading Spacemaster SX hoist. An innovative design that includes a large drum diameter gives the Spacemaster EX hoists the lowest headrooms and best wheel loads in the industry, while providing near true vertical lift with single reeving, as well as exceptional hook approaches and heights of lift. The Spacemaster EX hoist carries a Class I, Division 2 explosion proof rating for groups C and D and with a temperature class T3.

Standard Features

- Low headroom, normal headroom, and double girder trolleys

- 1.5 – 80 ton (1600 – 80,000 kg) capacities

- 460, 575/3/60 or 380/3/50 supply

- ASME H3 or ASME H4 duty [FEM 1Am, 2m, or 3m] rating

- Single reeved or double reeved

- Two-speed hoist with 6:1 ratio, contactor control

- Low maintenance, sealed hoist brake

- Two-speed trolley with 4:1 ratio, contactor control

- IP55/NEMA 4, 7 rated control panel

- CSA c/US approved

Designed for You

Like our Spacemaster SX hoist, each of our Spacemaster EX hazardous location hoists are configured specifically to your application. In addition to the standard features offered on the hoist, we offer many of our standard SX options as well as non-sparking options specific to the environments for the Class I, Division 2 explosion proof rating, including:

- Bronze coated hooks

- Brass wheels

- Brass drop lugs on the trolley

Downloads

Gallery

Qx® Wire Rope Crane

Qx® Wire Rope Crane

QX® wire rope cranes are complete crane systems, featuring our top-ranked Spacemaster® SX wire rope hoist.

About QX® Wire Rope Cranes

R&M crane packages are designed to work as a complete system, so every component, from the hoist selection to the bridge drives and girder size, are designed to work together. This means you are getting a fully optimized package to maximize your floor coverage and make the best use of your building space! Many of our innovative features are included as standard on the QX wire rope crane package, to bring you the best performance, safety, and reliability available in the industry.

Standard Features

- Spacemaster® SX wire rope hoist with two-speed hoisting controls

- Top or underrunning design

- C-track festoon electrification system with UL listed cables

- PRQ ergonomic pendant controller

- Optional Racon® 3 radio controller

- HoistMonitor® or HoistWatch load monitoring system

- Standard inverter controls for trolley and bridge for reduced load swing

- NEMA 4 type rated control enclosures

- Plug-in connections for easy assembly and maintenance*

- 208, 230, 460 or 575/3/60 power supplies, as well as 380/3/50.

- 115 volt control voltage for all power supplies (48 volt optional)

- All components are CSA c/US approved

Why choose a QX wire rope crane package?

QX crane packages are a total solution for your material handling needs. Your components are optimized to give you the right equipment, right when you need it! We have utilized our nearly 90 years in the material handling business to carefully engineer these packages to be tailored to any application or facility. Each package is designed specifically to make the most of your space, bringing you the best in safety, reliability and flexibility.

Better Safety

Every QX wire rope crane package comes equipped with a HoistMonitor or Hoistwatch load monitoring system. This system prevents overloads, monitors the equipment usage, and provides helpful advanced service warnings to help you keep your equipment running safely and avoid costly downtime. Our 4-position hoisting limit includes an innovate phase reversal position which prevents the block from running into and damaging the hoist in the event of phase reversal.

Less Maintenance

Sealed dust-proof brakes on the motors are self-adjusting and impregnated with Kevlar for high-performance wear, designed for over a million cycles. Standard inverter control motions on the trolley and bridge safely slows the motor speed to zero before the brake sets. This speed ramp up and ramp down time reduces load swing and extends the life of the motor brake. R&M is committed to helping you rise above with less maintenance, less downtime, lower repair costs — and reduced cost over the lifetime of your hoist equipment.

Downloads

Spacemaster SX Wire Rope Hoists Brochure

R&M Product Line Card Brochure

Gallery

Call Us Today

1-800-517-7247

To learn more about our complete lineup of industrial overhead crane systems; or for answers to other material handling questions give one of our friendly staff members a call directly at 1-800-517-7247 or