Customer Focused Solutions Driven

Solutions That Advance Businesses

Have a demanding application that falls outside the typical? Our highly experienced specialists ask the tough questions, then get to work to provide you with the best solution for your project. Our ability to supply turnkey solutions for challenging projects is unmatched in the industry.

Our work begins when others say it can’t be done. At Advanced, we design and build material handling systems for use in cleanroom, explosion proof, and corrosive environments. Whatever your project requires, Advanced has the experience to deliver specialty solutions that exceed expectations.

Limitless Capabilities Endless Possibilities

Crane and Material Handling Solutions for Any Industry

Aerospace

Renewable Energy

Automotive

Food & Beverage

Wastewater

Metals

Unrivaled Expertise Guaranteed Results

Solutions to Advance Your Business

Custom Tailored Expertly Delivered

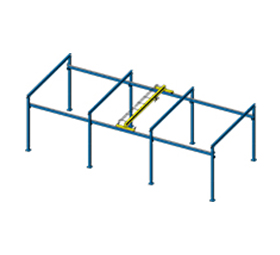

Gantry Crane Solutions That Perform

At Advanced, we listen closely to understand your project requirements. Only then can we determine the best solution for your application. It’s what we mean by Custom Tailored Expertly Delivered.

Since 2001, Advanced has been providing best-in-class material handling and fall protection solutions that exceed expectations. We offer a virtually endless selection of crane and material handling solutions all designed to keep your business safe and productive.

Contact us today at 1-800-517-7247 to learn how top running crane solutions that perform can advance your business.